Combine Cycle Power Plant-Engine + Steam Turbine

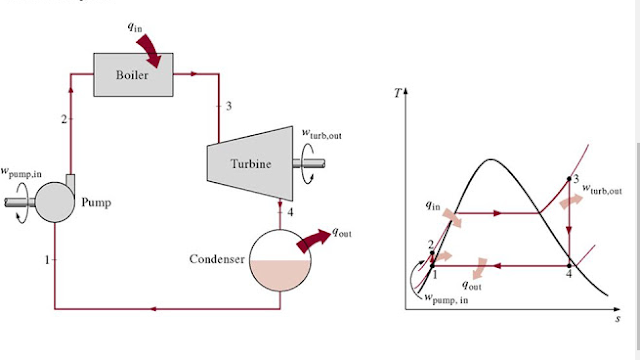

This combination combine Reciprocating Engine's(Otto cycle/Diesel cycle) and Steam Turbine's ( Rankine Cycle).The reciprocating engine's exhaust gases are made to pass through exhaust gas boiler which extract their energy to make steam which in turn use in steam turbine to convert it into electrical energy by electric generator.

These power plants have combine cycle efficiency of 45-48%.

This vapor cycle is also called Flexicycle. Wartsila is the most efficient engine manufacturer internationally with model 31 SG Engine to be world's most efficient Engine. For Flexicycle Overview

https://www.youtube.com/watch?v=NPI1P6ex9_Y

These power plant are of small capacity with power generation capacity ranging from a few MW to 400MW and these power plant are supportive plant for emergency power source or for any maintenance work taken as stand by for bigger power plant such CCPP(gas turbine+steam turbine) and Steam turbine of Capacity from 1200MW to 4800MW and also for Hydel Power Plant of capacity from 150MW to 22000MW.

Engines' efficiency depend upon the category like Slow, Medium and High speed engine with slow speed engine to be more efficient (45-50%)as the thermal process efficiently followed in them as compared to that in medium/high speed.

And Diesel Engines are less efficient than petrol engine but their power producing range are much higher than that of petrol engine as their compression ratio (15 to 23) is higher as compared to that of petrol engine (8 to 12).

Diesel engines are often run on furnace oil which is cheap but having less calorific value and render engines to higher maintenance outages. And these engine produce more environmental problem as this fuel is most dirty fuel from refineries.

With the readily available less fuel cost of Gas fuel( LNG, CNG), with lower maintenance routines gas engines run on Otto cycle are becoming more famous in today's energy mix.

Gas engines CC power plant are of less power producing capacity (5MW to 100MW ) as compared to Diesel Engine CC power plants.

Gas engines power plants are cleaner and required less auxiliary equipment because of cleaner fuel as compared to that diesel engines. So installation cost and auxiliary load are lesser for gas engine CC power plants.